; Date: Fri Apr 06 2018

Tags: Computer Hardware »»»» Apple iPhone Hardware »»»» iPhone »»»» Strange Parts »»»»

Price any Apple hardware and you'll find they charge a pretty penny for larger memory capacity. In Apple's latest design iterations it is getting harder and harder to make upgrades, and upgrading iPhone memory or storage capacity has never been possible. You could say Apple's whole business model is predicated on charging a premium for memory and storage.

For example - a current model MacBook Pro, upgrading to 16GB memory costs $200 when the consumer-level price for 16 GB memory sticks is well under $100. For a 512GB SSD drive costs $400 when the street price is under to $200.

For an iPhone the price difference between 32GB and 128GB storage is $100, and I'd hazard a guess that a 128GB SSD doesn't cost $100. Sure enough, on Amazon an M.2 128GB SSD card is about $67 from several vendors.

The video here goes through the steps required for a DIY upgrade of an iPhone storage unit.

Apple's engineering did their best to make it a difficult task. The techical purpose Apple has is making the phones as slim and light-weight as possible. That goal means the parts are soldered to the board in a way that's difficult to remove and then install a new chip. Plus there's the task of duplicating the existing flash drive into the replacement drive.

Steps are:

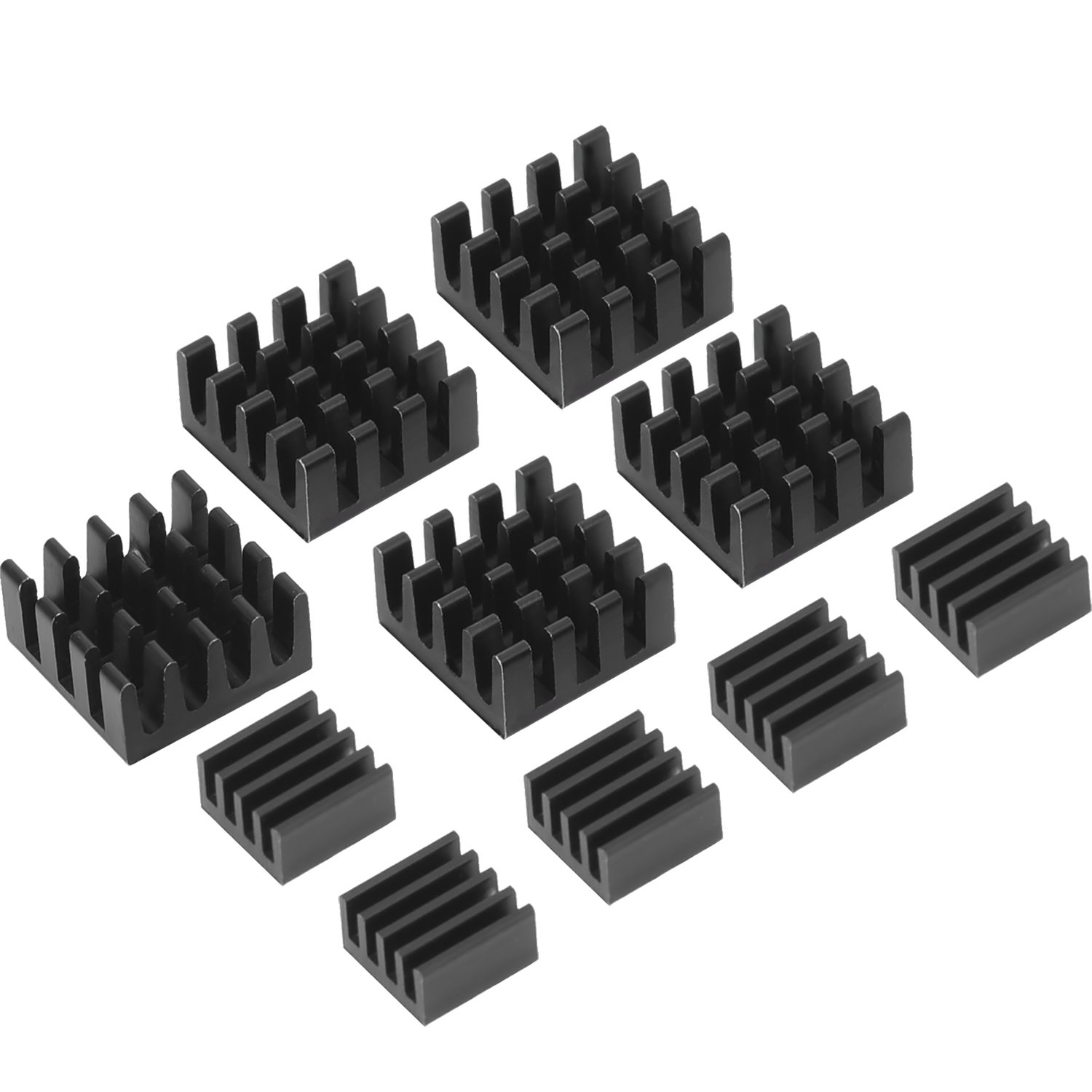

- Learn how to safely desolder the flash-drive chip from the logic board without damaging other components on the board.

- Requires a heat gun

- Requires a holder that prevents the SIM card holder from being damaged

- Requires using a shield to prevent other parts from getting heated

- Requires practice -- Scotty went through over 10 logic boards on trial runs before having the confidence to do it on his actual phone

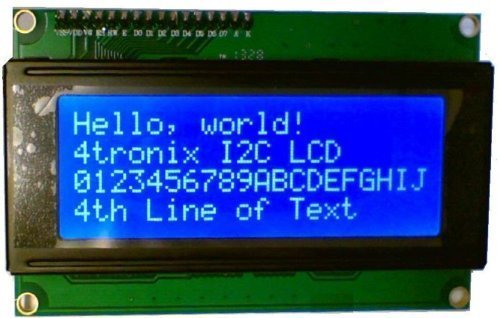

- Specialized device to read the flash drive from the old phone, and write the contents to a new flash drive

- There is a manufacturer for such a specialized device, Scotty shows how to use that device

- The device can edit some settings while copying contents

- It's basically a file-system copying device that can also resize the filesystem

- Soldering the new flash chip to the logic board

- A metal shim is used that has a pattern of hole where solder needs to sit

- The shim is positioned on top of the flash drive chip

- "Solder paste" is smeared on that shim such that solder balls form at the correct locations

- A heat gun is used to melt the solder so it stays on the chip

- Once the chip has the solder balls, it can be positioned on the logic board and a heat gun is used to solder the chip to the board

- Reassembling the phone and booting up