; Date: Thu Jul 22 2021

Tags: Network Attached Storage »»»» Direct Attach Storage »»»»

Looking at the prices and features of NAS devices like QNAP, Synology or Drobo, you might think it requires specialized parts at a high price. In reality, disk drives have standardized mounting holes, using standardized screws, and it's possible to build simple drive cages for a fraction of the price. To turn the do-it-yourself (DIY) drive cage into a data storage solution requires a couple more parts, such as a computer and some USB adapters. But the starting point is to build a low cost DIY drive cage.

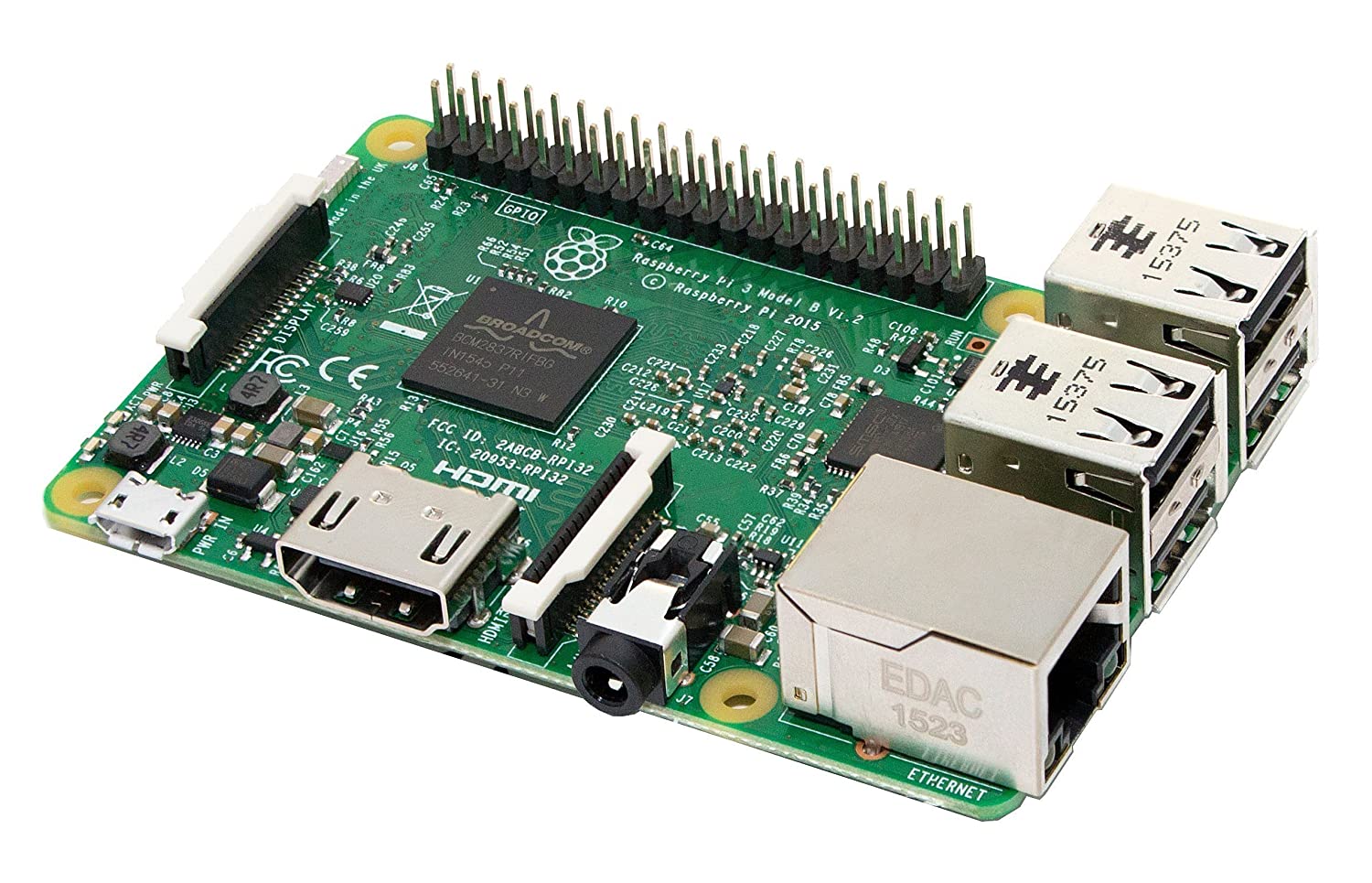

Building a do-it-yourself NAS or storage array requires a drive cage to hold several hard disks, a computer to drive the NAS portion, adapter cables to interface that computer to the drives, and a power supply for the drives and computer. One possible approach is to simply get a mid-tower PC with enough internal drive bays, install Linux, install Open Media Vault, and you're good to go. But what if you're interested in a Raspberry Pi (or other single board computer)? In this article we'll focus, therefore, on the simplest drive cage designs for holding standard sized 3.5 inch or 2.5 inch hard drives.

Open Media Vault is an open source software package running on Linux, and compatible with both x86 and ARM processors. With it, you can scan available hard drives, format the drives for Linux, mount them on Linux, and make data storage volumes available to mount either with SMB and NFS. This means Open Media Vault is compatible with Windows, macOS, and Linux systems.

With OMV, and a suitable host computer, you can build the functional equivalent to the professionally designed NAS devices. You'll be in control of the hardware and software, and it's not that hard to do. But, let's stay focused on the topic of building a simple inexpensive hard drive cage.

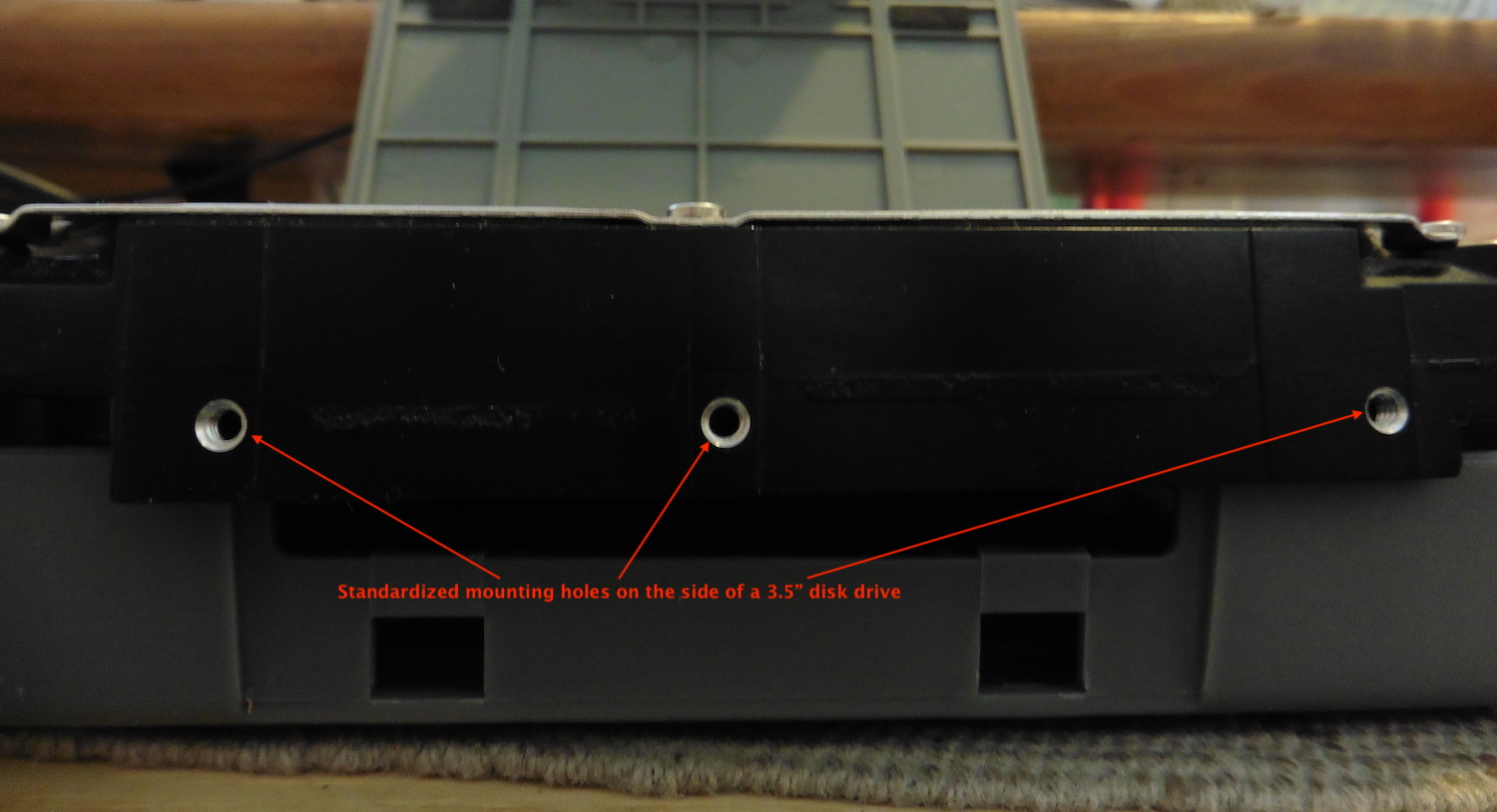

An important data point to know is the correct size screws for the mounting holes on both 2.5 inch and 3.5 inch hard drives. Here's what I mean:

Both the 2.5 inch and 3.5 inch drives have standardized screw hole locations, and standardized screw threads. This means you can use standard screws that can be bought at any hardware store. You don't have to buy special purpose computer screws, because hard drives use standardized screws.

- For 2.5 inch drives: Use M3x3mm screws, that is the M3 screw and approximately 3mm length.

- For 3.5 inch drives: Use 6/32 screws, approximately 1/4 inch length.

With this knowledge, in the hardware store you can buy the required screws and various kinds of metal pieces, and come up with a DIY hard drive cage. For example:

It doesn't take too much thinking to realize you could cut angle iron pieces at the desired lengths, then use some 6/32 screws to hold the disk drives in place. The downside is this looks very non-professional, and will probably be wobbly. The last thing you want for data storage is a wobbly disk drive cage.

In the rest of this article we'll go over several products that are more polished than the rough prototype we just discussed. It seems that some product designers already had this particular inspiration, and put together preconfigured kits. You can buy these kits on eBay, Amazon, NewEgg, or other electronics retailers.

Building a DIY hard drive cage is only the first step of building a DIY NAS system. The products shown below are simply the physical hardware required to connect hard drives into a workable drive cage. Not included are power supplies, adapter cables, and fans (except for the one instance).

One route for building a NAS using hard drives in a simple metal cage involves a Raspberry Pi, some USB-SATA interface boards, and other parts:

- USB3-to-SATA boards or adapter cables.

- It is easy to find inexpensive adapter cables for 2.5" hard drives. In such cases the drive will be powered over the USB bus, and it's best to use a powered USB hub.

- To support 3.5" drives, requires a power supply for the drive, and there are adapter cables that come with a suitable power brick.

- Buy a USB3 hub

- Connect a Raspberry Pi 4B to the USB hub

- Configure the RPI to boot from USB, and configure one of the drives with a Raspberry Pi operating system

- Install Open Media Vault

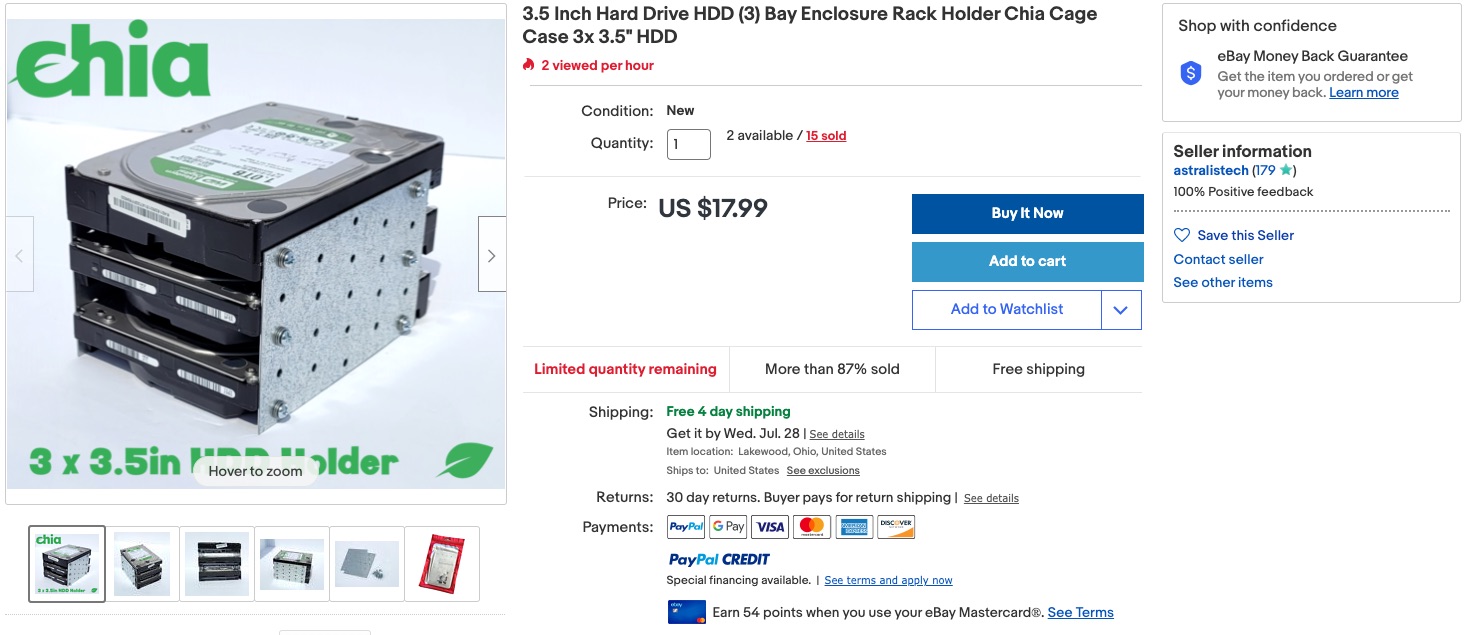

3.5 Inch Hard Drive HDD (3) Bay Enclosure Rack Holder Chia Cage Case 3x 3.5" HDD

This is not so different from the angle iron idea, is it? It is literally two pieces of steel plate, with pre-drilled holes, and a packet of 6/32 screws.

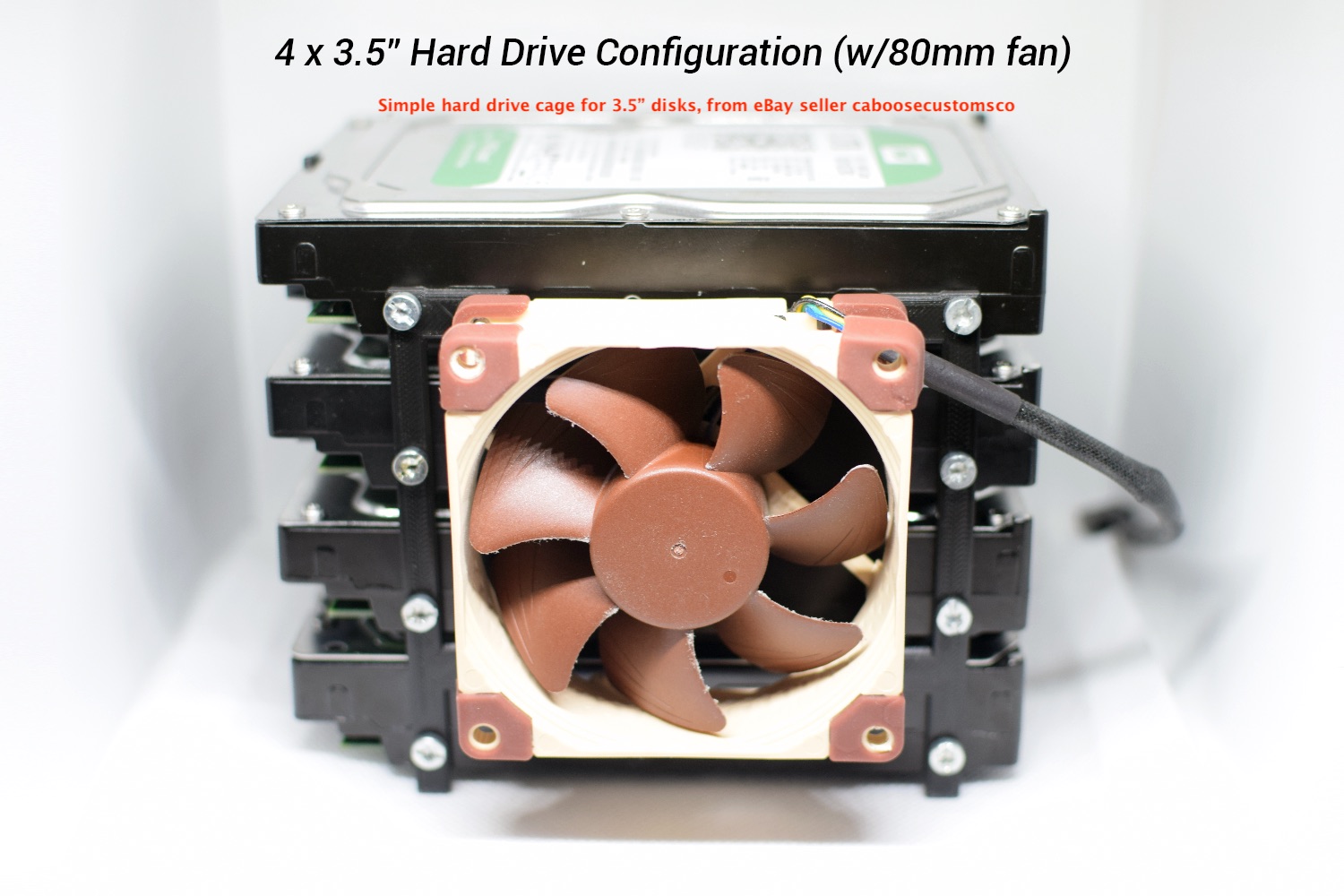

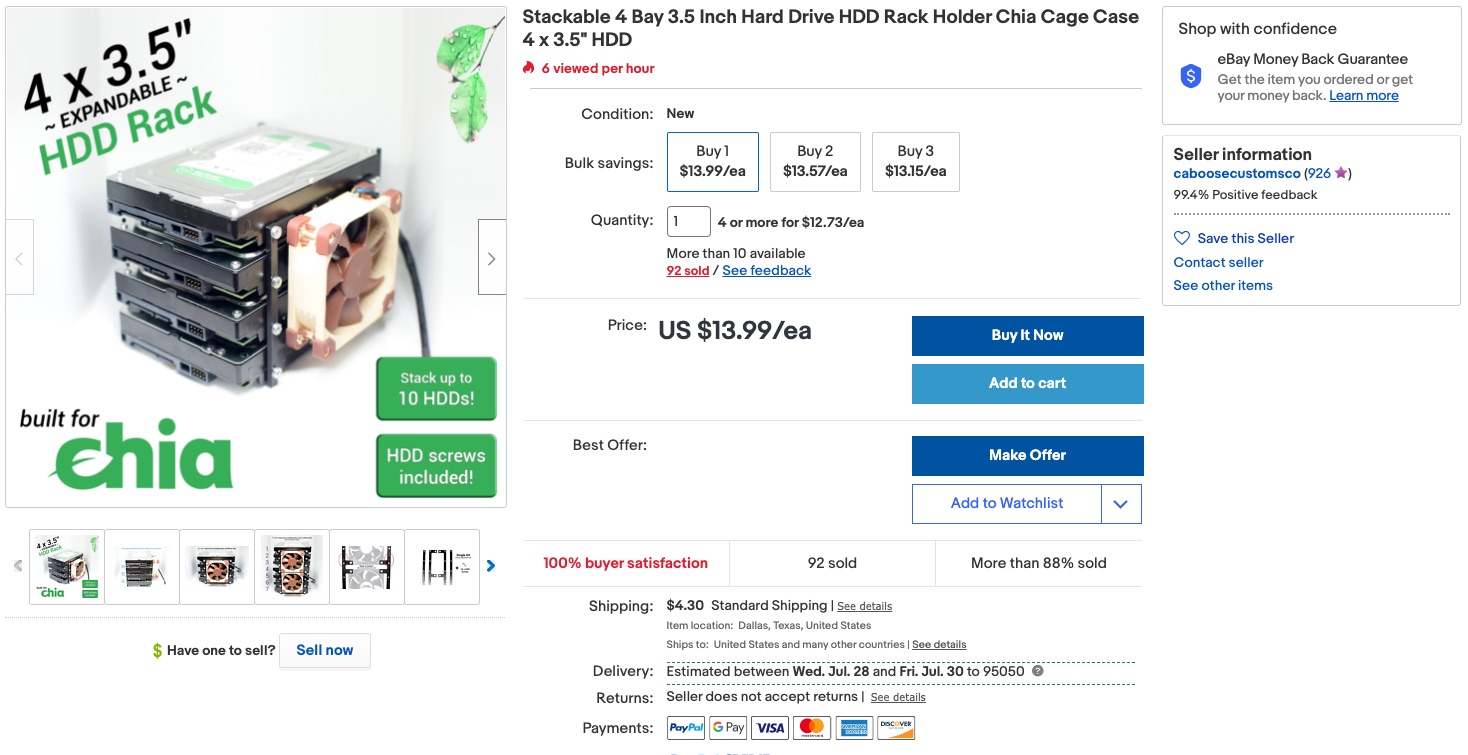

Stackable 4 Bay 3.5 Inch Hard Drive HDD Rack Holder Chia Cage Case 4 x 3.5" HDD

This is has two improvements. First, the design is stackable, meaning you can buy multiple bracket kits and connect them together. Second, it includes a fan to keep the drives cool.

It is still literally pieces of metal and some screws.

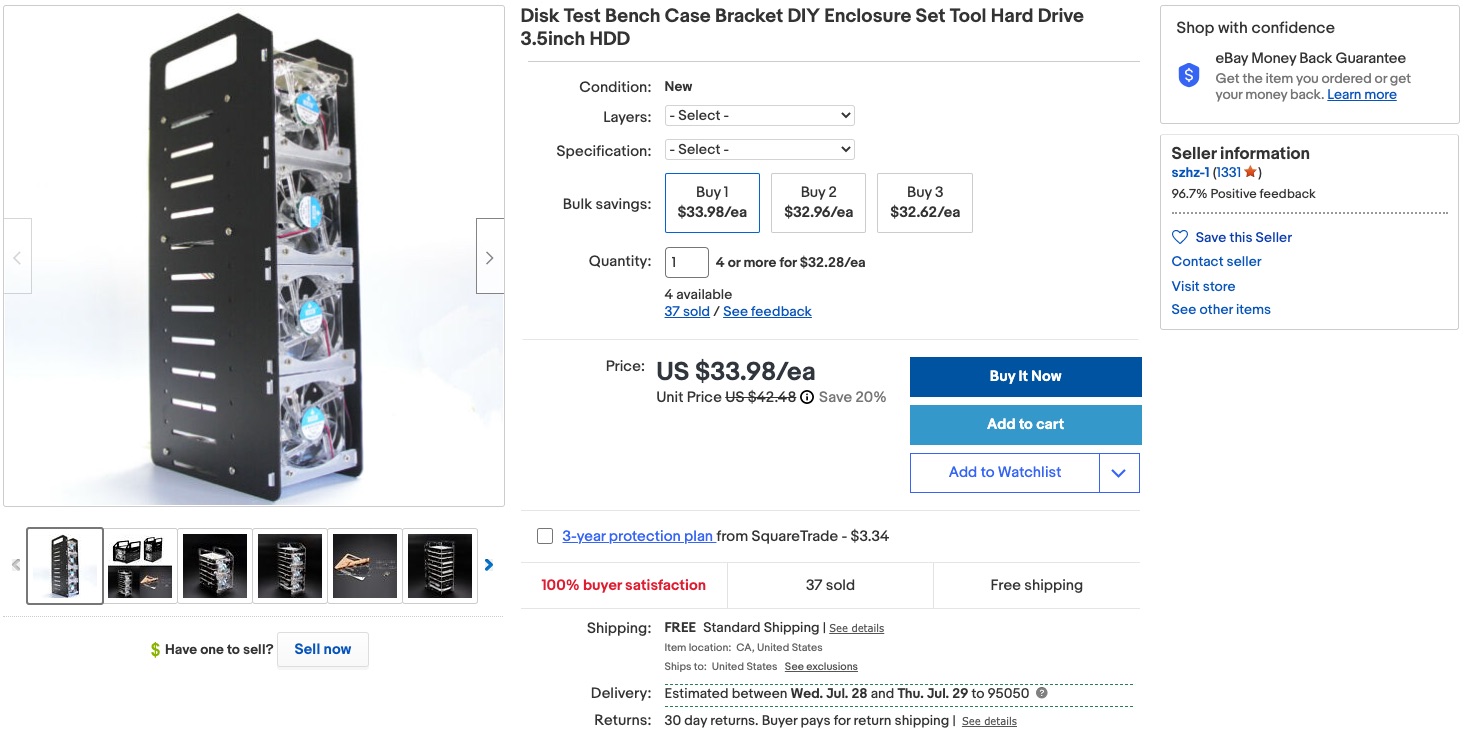

Disk Test Bench Case Bracket DIY Enclosure Set Tool Hard Drive 3.5inch HDD

This design uses acrylic sheets, rather than metal. Otherwise it is a similar idea.

There are two side acrylic pieces providing the basic structure, and several cross-bar pieces for horizontal stability. You slot them together, and it contains shelves. You simply place the hard drives on the shelves rather than screw the drives in place.

The fans shown in this picture are not included.

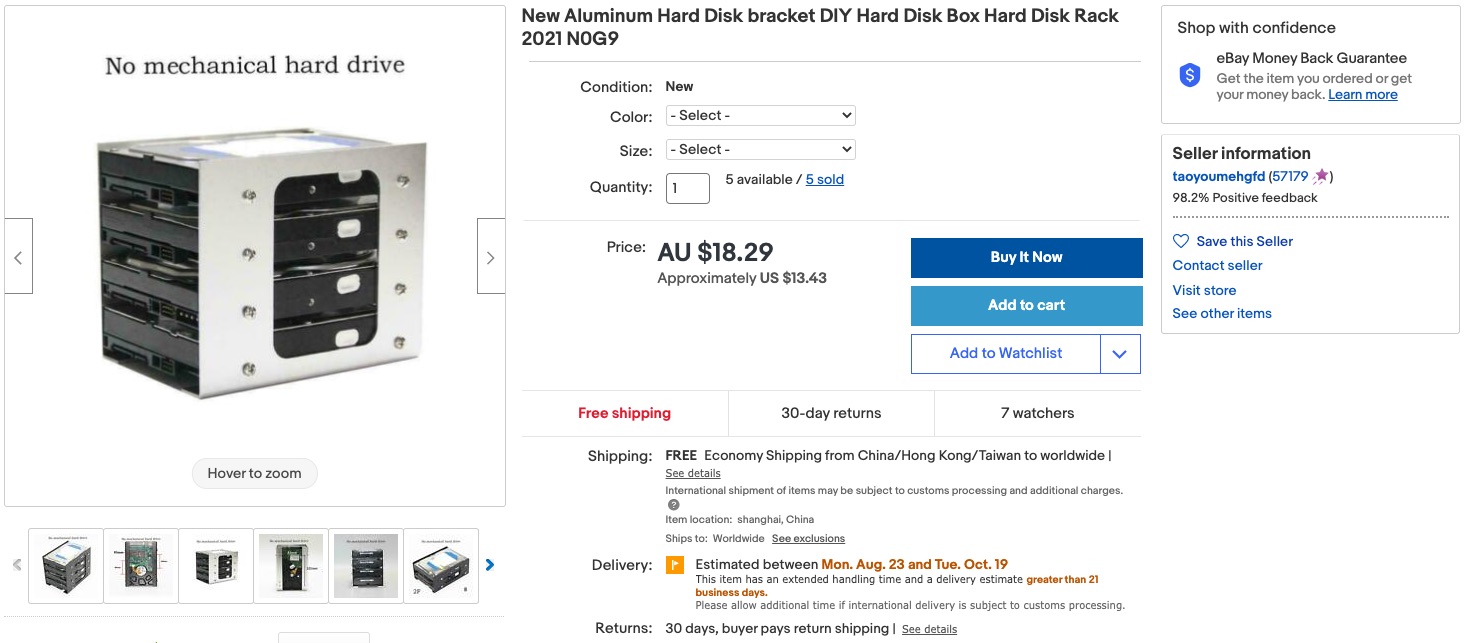

New Aluminum Hard Disk bracket DIY Hard Disk Box Hard Disk Rack 2021 N0G9

This product is listed with a price in Australian currency, but it ships from Shanghai, and they say they'll ship worldwide. Surely you can find a listing in US Dollars?

In any case, this is the same solution as above. Literally, this is two metal brackets with predrilled holes, and some 6/32 screws.

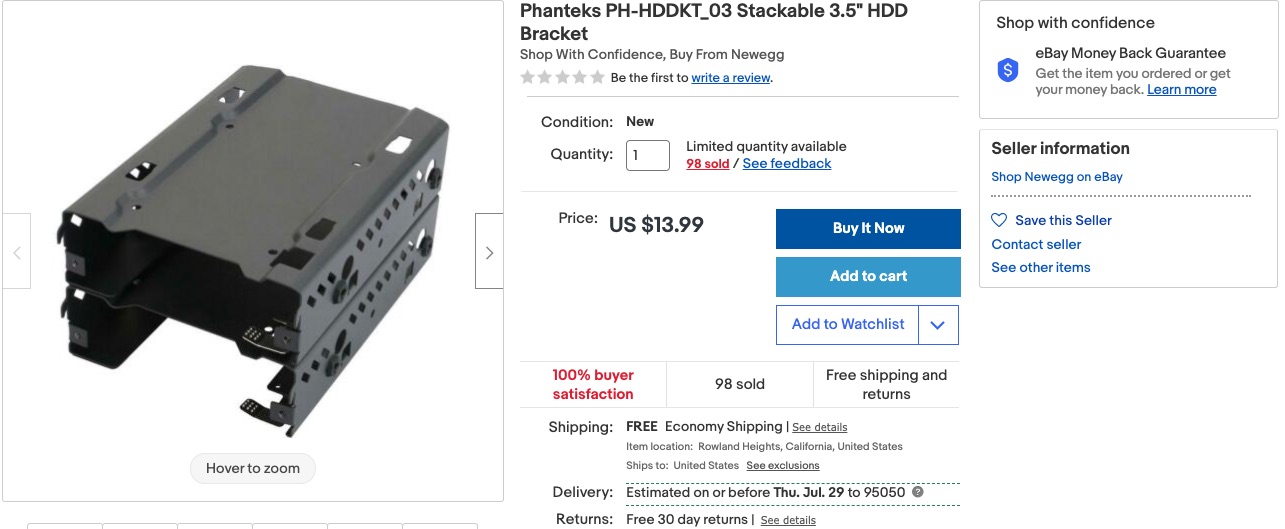

Phanteks PH-HDDKT_03 Stackable 3.5" HDD Bracket

This design is a departure from the simple pieces of metal shown previously.

It is purpose designed as a hard drive cage. It's essence is still pieces of metal, and standardized screws, but at least in this case the metal is shaped specifically for this purpose. The design is stackable, and it appears to be more rigid than the other solutions shown here.